Contract Machining

Contract Machining

System Components, Inc., well known throughout the industry for quality and competitively priced couplings, offers an entire division dedicated to custom machining. We skillfully machine gray iron, aluminum, low to medium carbon and alloy steels, ductile iron, and many other materials. Our full-service capabilities and equipment bring a new level of precision to CNC machining. System Components is known for high-quality precision machining and value-added service.

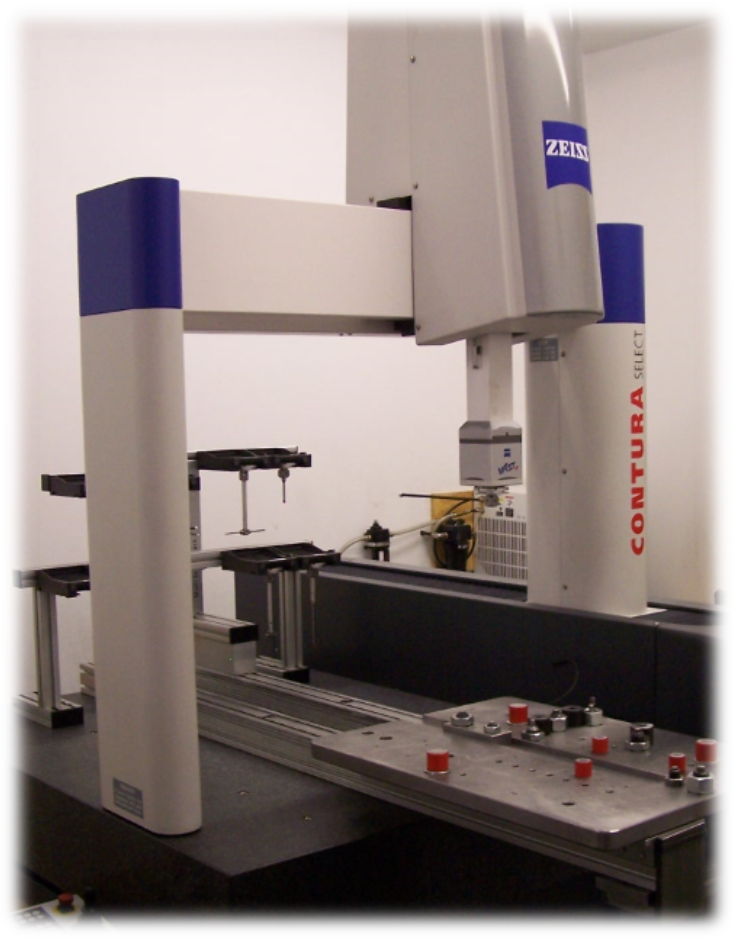

New ideas take shape with precision CNC machining at System Components, Inc. Prototype engineering, precision machining, CMM verification, special packaging - our complete service provides the best source for your quality contract machining.

We proudly use ISO 9001 as a standard and consistently produce value-added solutions to help our customers gain the competitive edge. Our devotion to quality products and meticulous service galvanizes customer loyalty. We use state-of-the-art manufacturing equipment to make products to stringent specifications and quality standards and continuously improve our products and processes.

Wire Electrical Discharge Machining (Wire EDM)

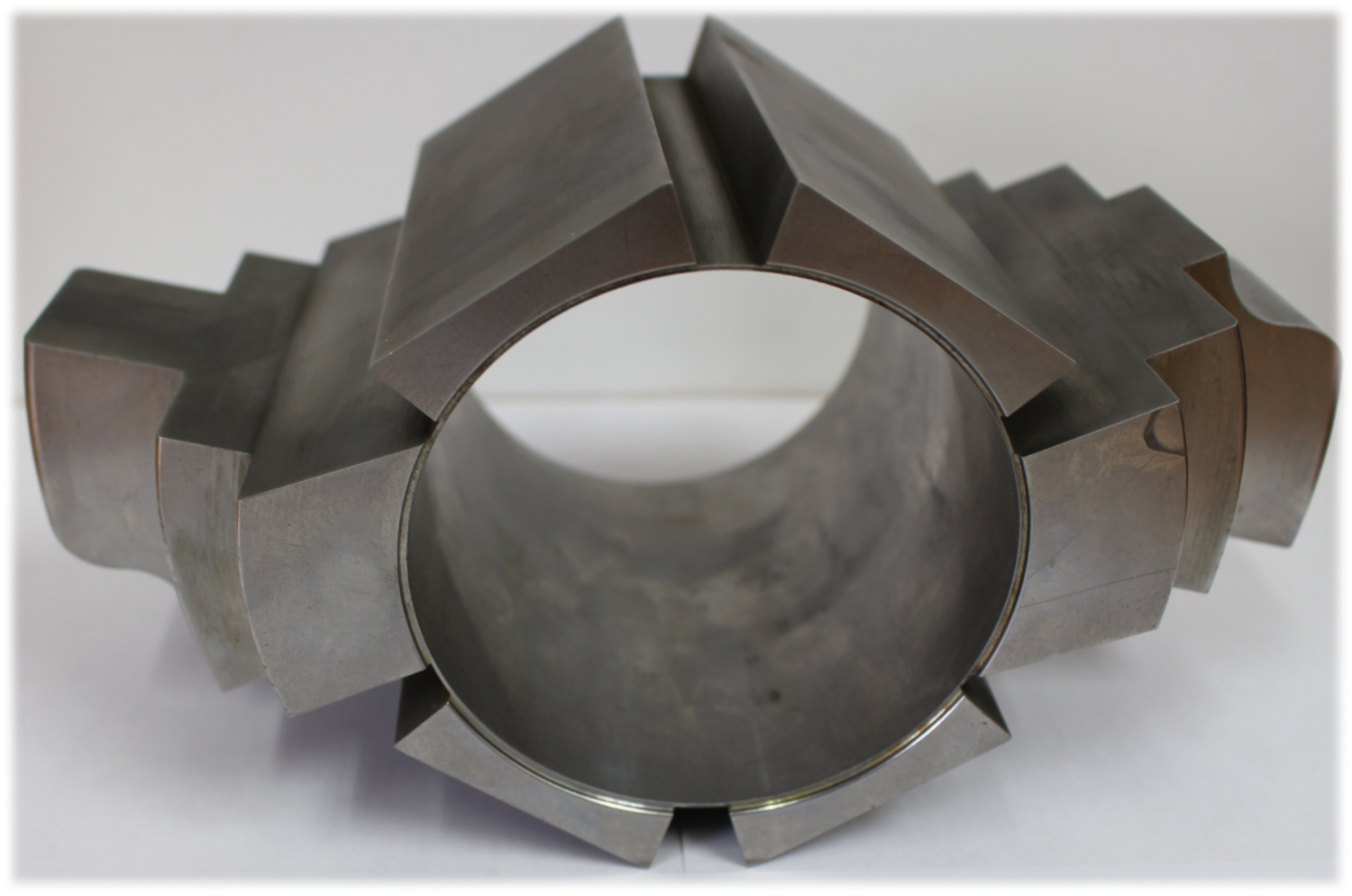

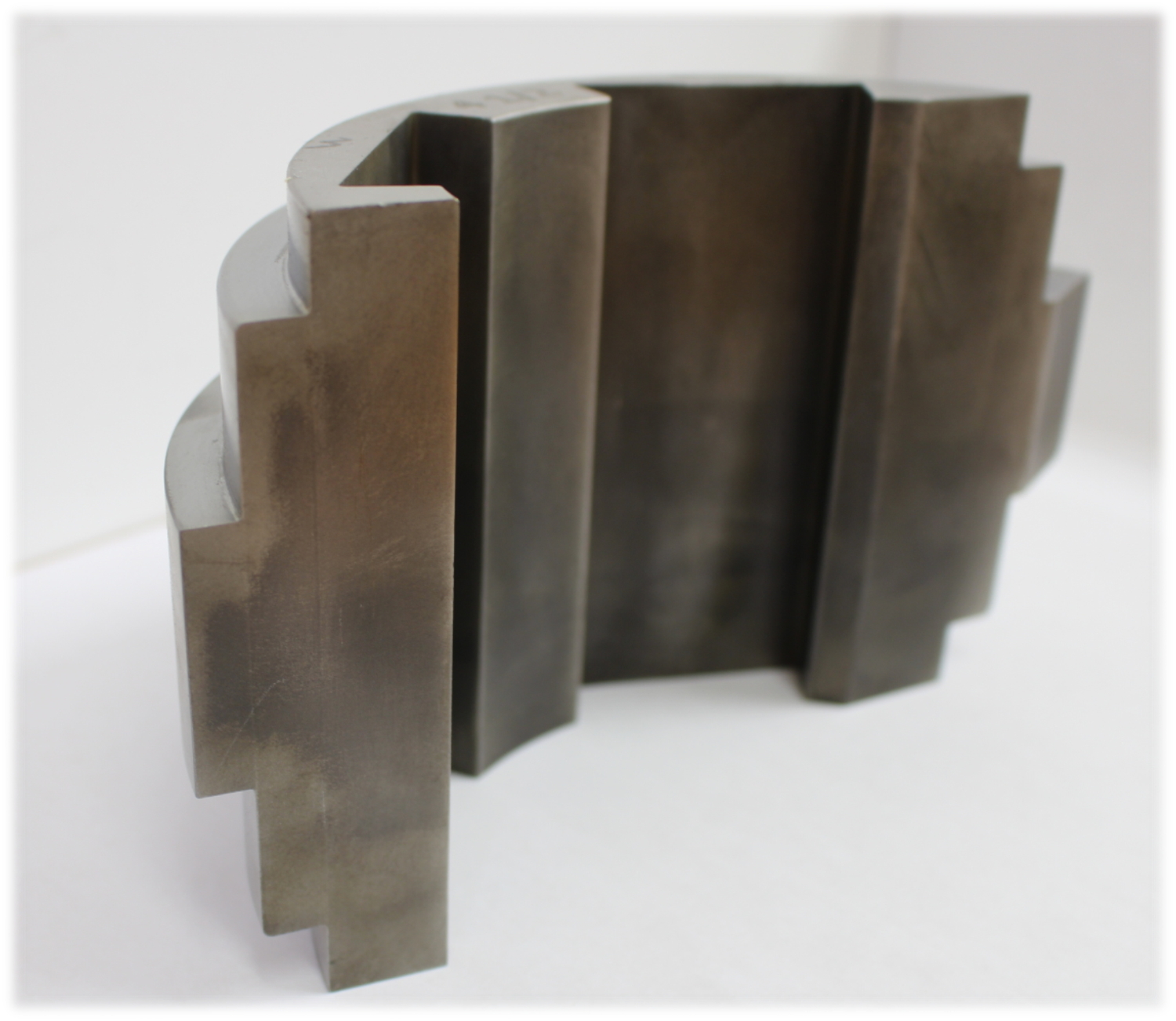

Wire EDM offers endless possibilities. Wire Electrical Discharge Machining cuts material with a thin wire electrode. Electrically charged wire removes material resulting in a finished product with no burrs or distortion. The wire travels on a pre-programmed path making complex shapes with accurate tolerances. Wire EDM precision can cut a square into the top of a piece tapering to a circle at the bottom.

Specifically…

- Maximum allowable dimensions 46” x 45” x 23”

- Maximum weight 11,000 LBS

- Production runs up to 24 pieces

Click here to Request for Quote or call us today at 1-800-866-1290.